3D printed thermoforming mould for packaging

D2M to showcase innovative 3D packing solutions

DUBAI, March 25, 2015

D2M Solutions, a Dubai-based leading technology supplier to the Middle East industrial sector, is set to showcase a new world of packaging 3D design through to manufacture at a leading print and pack show in the emirate next month.

The Gulf Print & Pack 2015 will run from April 13 to 16 at the Dubai World Trade Centre.

It will show how to create innovate packing solutions that will challenge both the aesthetic and functional norms, said a statement.

D2M is a Stratsys, platinum partner, and is a select member company forming Stsratasys Direct Manufacturing Global Network, with an impressive multi-system, in-house ‘3D printing factor’ to provide on-demand 3D printing services to the Middle East region, it said.

The firm will put a spotlight on 3D virtual design, 3D scanning and 3D printing in the highly competitive consumer packaging sector for the ultimate in packaging design and functionality.

It has experts to take show visitors through all the stages of developing new packaging, from the 3D virtual design concept, or reverse engineering of an existing packaging product for the development of packaging moulds or new packaging products; through to 3D printing of prototype packaging, or prototype packaging moulds.

The consumer products’ packaging is a fast-moving competitive sector with increasing challenges for packaging design and manufacture to be attractive on the shop shelf, but at the same time fulfill functional requirements and eco-friendly-demands of today’s conscientious consumer.

To address these challenges, and differentiate on the retail floor, packaging manufacturers can now create 3D ‘virtual products,’ that fulfill all their testing and development needs before proceeding to production.

‘The Perfect Package,’ 3D Experience software from Dassault Systems, is tailored to anticipate the needs of the consumer packaging sector by simply providing the most effective 3D virtual design tools to realistically visualise packaging design and analyse and test its performance before proceeding to actual production - helping to cut design time and material costs by up to 50 per cent.

The companies can eliminate packaging recalls and quality issues, but at the same time, make use of existing designs to accelerate into new markets without the expense of new packaging development costs.

“For really rapid packaging designs, existing products can be 3D scanned to obtain the physical geometry of packaging in a few minutes. This is a great way to kick-off new packaging design, because the data captured by the scanner can be manipulated to create product updates and changes in a very short time,” according to a statement D2M spokesperson.

“Additionally this data can be used to create custom-fitted packaging for products even for irregular shaped items, and at the same time minimise the materials needed,” it said.

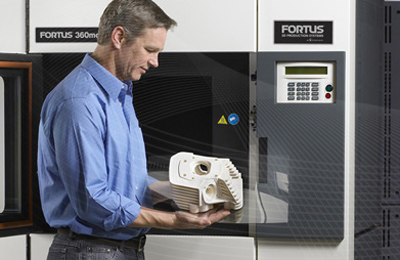

“It’s not yet widely known, but the materials used in industrial quality 3D printers are now so robust and versatile that moulds for packaging can simply and accurately be 3D printed - meaning weeks or even months can be shaved off the development times needed to create new product packaging in comparison with using traditional methods,” said the statement.

“3D printing is now being used for blow-molds, and thermo/vacuum -forming for packaging. 3D printing is mainly used for prototype packaging molds, but short runs and product trials for final approvals can be created ‘on-demand’ in this highly dynamic sector,” it said.

In addition to showing technologies directly tailored to the printing and packaging sectors, D2M will be printing prototype packaging in the Gulf Print and Packaging show, and will have some impressive examples of 3D printing uses in the wider industrial arena. - TradeArabia News Service