Ingersoll Rand launches next-generation compressors

DUBAI, May 30, 2017

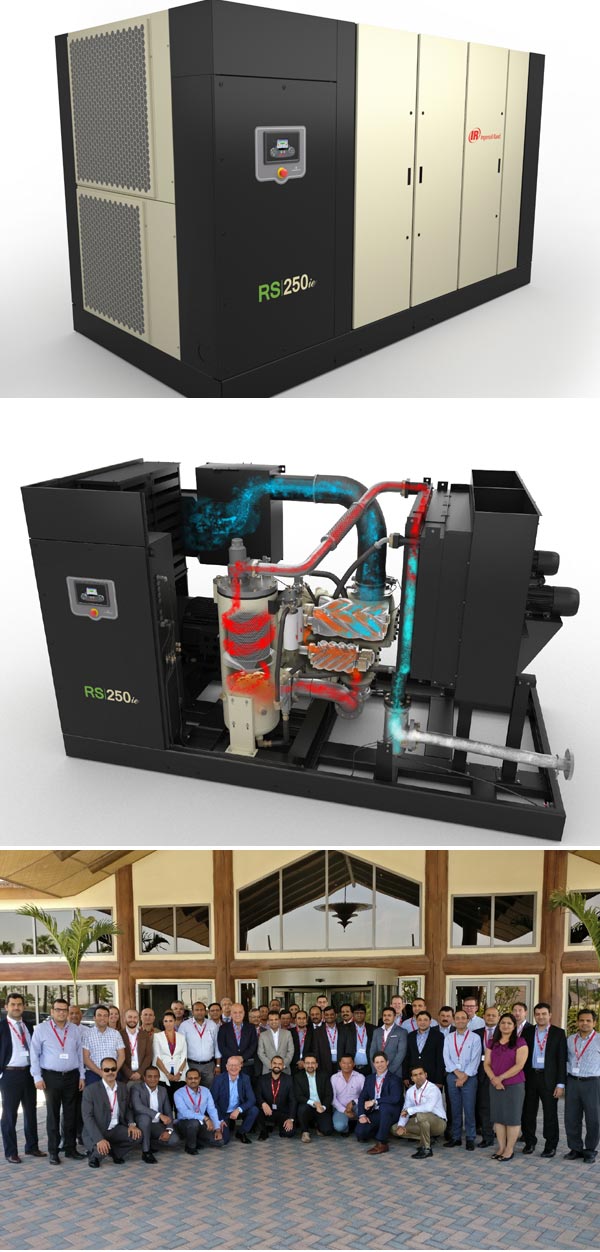

Ingersoll Rand, a global leader in compression technologies and services, introduced its new models of the next-generation R-Series oil-flooded rotary screw air compressors at an event in Dubai, UAE, last week.

The new models provide a more energy-efficient solution for customers with high capacity air requirements, the company said.

The event gathered more than 30 representatives from distributors from the UAE, Saudi Arabia, Pakistan, Egypt, Lebanon, Kuwait, Jordan, Bahrain, Qatar, Libya and Iraq.

The launch included discussions on how, by taking a total systems approach, operations can increase performance and reduce inefficiencies for significant bottom-line benefit.

The new RS200 to RS250 models are available with the new, state-of-the-art single-stage airend, or the two-stage airend that increases airflow by up to 16 percent. The new fixed-speed models are 10 per cent more efficient compared to legacy products, while the variable speed option is up to 35 per cent more efficient compared to the industry average, the company said.

“The ability of these compressors to deliver outstanding efficiency without compromising reliability meets the increasing demands of industries to increase productivity while reducing energy use,” Kevin Kosobud, portfolio leader, oil flooded compressors for compression technologies and services at Ingersoll Rand at Ingersoll Rand. “Our next-generation R-Series RS200 to RS250 models help customers increase overall system reliability and decrease their total cost of ownership with new state-of-the-art features and performance enhancements that save them tens of thousands of Euros.”

Ingersoll Rand has added these models to the next-generation R-Series portfolio allowing customers who run 24/7 and rely on large amounts of compressed air to have equipment that is as reliable as their demand.

The RS200 to RS250 kW models are the third introduction to the next-generation R-Series line of compressors, following the next-generation R-Series 30 to 37 kW fixed-speed and variable speed drive introductions in 2015 and 2016.

At the core of every Ingersoll Rand next-generation R-Series compressor is an airend that is specifically designed to improve overall system efficiency. In addition to the enhanced single-stage airend, the RS200 to RS250 models are also available with the new two-stage airend. This two-stage airend is the most efficient airend available today.

Each compressor comes standard with Progressive Adaptive Control (PAC) protection, V-Shield technology, floating coolers and Ultra EL lubricant. These features help keep equipment running efficiently and maximise uptime for facilities that are manufacturing around the clock.

All next-generation R-Series air compressors are equipped with Xe-series controllers, which allow easy, intuitive access to, and control of, the compressed air system. The Xe145 controller has built-in performance analysis and graphical trending, as well as built-in sequencing for up to four compressors. – TradeArabia News Service